1. Handling - Please handle the ball screws carefully. DO NOT remove the ball nut from the ball screw. Specialized tools and skills are needed to mount the ball nut properly.

2. Lubrication - Please lubricate the ball screws frequently, at least once per week. Lithium grease is a good option for general purpose use (for example Mobil 1 Blue Synthetic Grease). Remember, any lubricant is better than no lubricant!

3. Fitting - It is normal for the machined end of the ball screw to fit very snugly into the support. We suggest that you shrink the ball screw prior to installation by placing it in your freezer for a couple of hours. If necessary, a rubber mallet may be used to gently coax the support onto the ball screw.

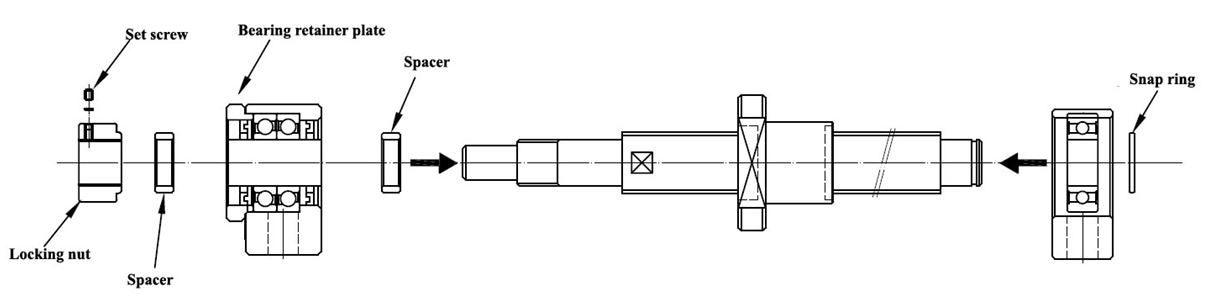

Installation Diagram

Technical Drawings

1605 Ball Screw

1204 Ball Screw Drawing

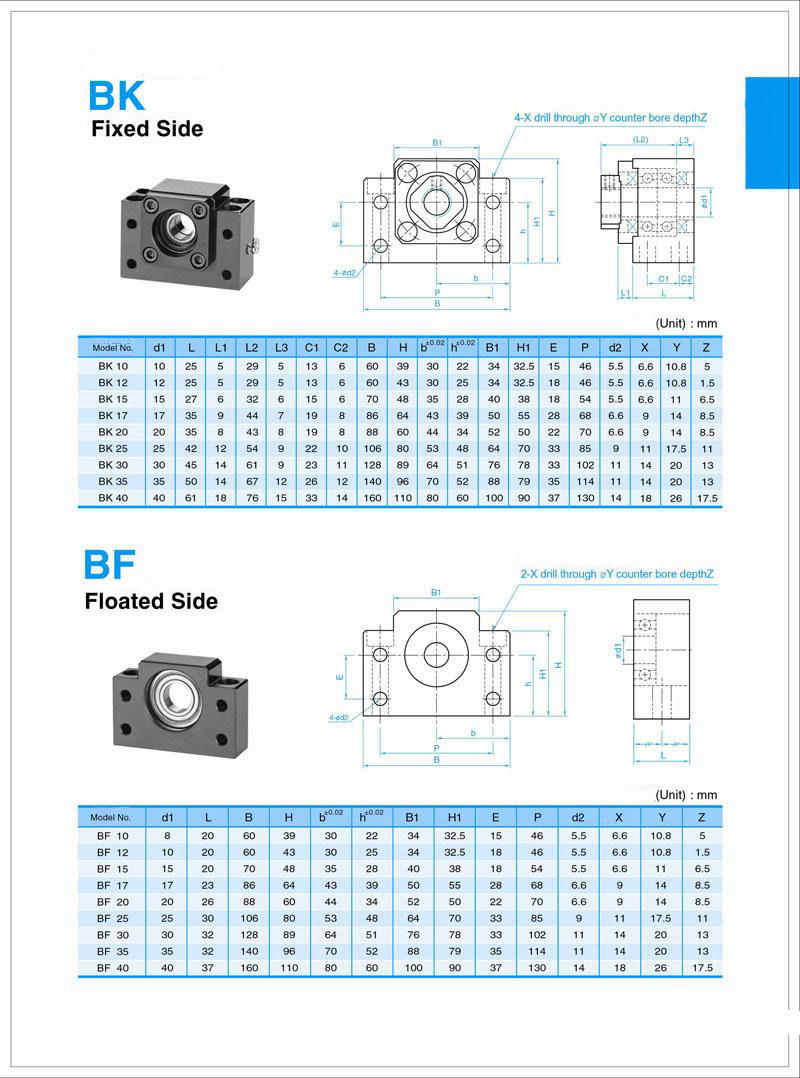

BF/BK End Support

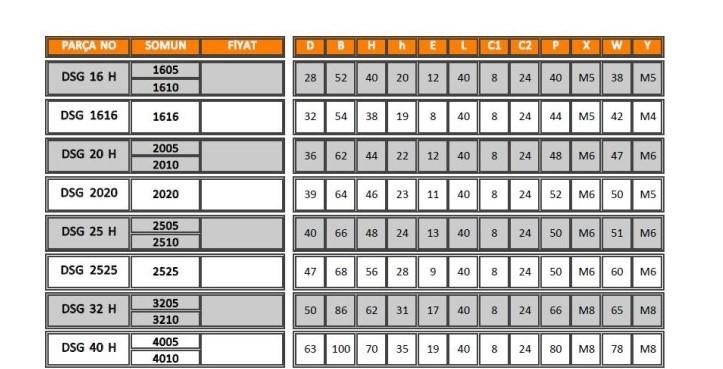

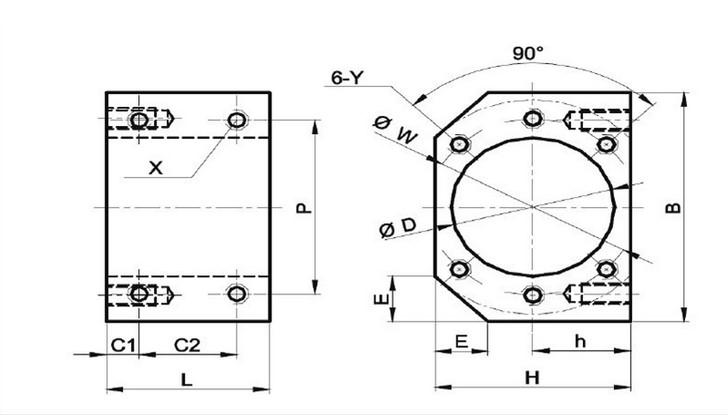

DSG Ball nut mounting block

DSG12H D=22.1 B=50 H=35 h=15 L=36 C1=6 C2=24 P=35 X=M5 W=32 Y=M4 (unit: mm)